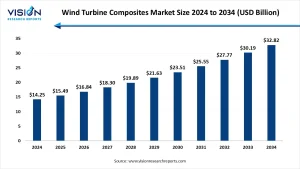

The global wind turbine composites market size was estimated at around USD 14.25 billion in 2024 and it is projected to hit around USD 32.82 billion by 2034, growing at a CAGR of 8.70% from 2025 to 2034.

Get a Sample@https://www.visionresearchreports.com/report/sample/41673

The wind turbine composites market is playing a pivotal role in the global shift toward renewable energy. These advanced materials primarily glass fiber and carbon fiber reinforced composites are integral to manufacturing lightweight, durable, and high-performance wind turbine blades and components. As nations commit to reducing carbon emissions and expanding wind energy capacity, demand for composites in turbine manufacturing is surging.

Wind Turbine Composites Market Growth

The global wind turbine composites market was valued at approximately USD 14.25 billion in 2024. With the continuous expansion of wind energy projects across the globe, the market is expected to grow robustly, reaching an estimated USD 32.82 billion by 2034. This growth reflects a healthy compound annual growth rate (CAGR) of 8.70% from 2025 to 2034, driven by the increasing emphasis on energy transition and sustainable infrastructure.

Several factors are accelerating market expansion. These include rising investments in offshore wind energy, rapid technological advancements in blade manufacturing, and favorable government policies supporting renewable energy installations. The increasing length of wind turbine blades also necessitates the use of high-strength, lightweight materials, reinforcing the importance of composites.

Wind Turbine Composites Market Dynamics

Market Dynamics

- Decarbonization and Renewable Energy Demand: Global initiatives aimed at reducing carbon emissions are accelerating the adoption of wind energy, thereby driving demand for high-performance composite materials.

- Technological Advancements: Innovations in composite formulations (e.g., carbon fiber, hybrid composites) and manufacturing processes (e.g., resin infusion, automated layup) are enabling the production of longer, lighter, and more efficient turbine blades.

- OEM-Supplier Collaboration: Increasing partnerships between turbine manufacturers and composite material providers are fostering innovation in recyclable and cost-effective materials.

Opportunities

- Emergence of Recyclable Composites: New developments in thermoplastic composites and recyclable thermoset resins are opening pathways for sustainable lifecycle management.

- Offshore Wind Expansion: Growth in offshore wind installations, which require larger and more durable blades, presents a significant opportunity for advanced composite applications.

- Localization and Vertical Integration: Regional manufacturing and integration of supply chains offer potential to reduce costs and lead times, especially in emerging wind markets.

Challenges

- High Material Costs: Advanced composites such as carbon fiber are expensive, which can impact the overall economics of wind projects.

- Recycling and End-of-Life Management: Traditional thermoset composites are difficult to recycle, posing environmental and regulatory challenges.

- Supply Chain Volatility: Raw material shortages, transportation bottlenecks, and geopolitical risks can disrupt production and delivery timelines.

- Manufacturing Complexity: Scaling up production for large turbine blades requires significant technical expertise and capital investment.

Wind Turbine Composites Market Trends

- Increased Use of Carbon Fiber Composites: Manufacturers are shifting toward carbon fiber for its superior strength-to-weight ratio, especially in offshore wind turbine applications.

- Automation in Blade Manufacturing: Adoption of automated composite processing technologies is improving production efficiency and consistency.

- Sustainable Composite Solutions: There is growing interest in recyclable and bio-based composites to align with environmental regulations and sustainability goals.

- Geographic Expansion of Wind Projects: Emerging markets in Asia-Pacific, Latin America, and Africa are witnessing significant growth in wind energy infrastructure, driving composite demand.

Read More:https://www.heathcareinsights.com/infectious-disease-in-vitro-diagnostics/

Top Companies in Wind Turbine Composites Market

- Owens Corning

- Hexcel Corporation

- Gurit Holding AG

- Jushi Group Co., Ltd.

- Toray Industries, Inc.

- SGL Carbon SE

- Mitsubishi Chemical Holdings Corporation

- AOC Aliancys Chemicals

- Teijin Limited

- Zhejiang Hengyi Group Co., Ltd

Wind Turbine Composites Market Segments

By Fiber Type

- Glass Fiber Composites

- Carbon Fiber Composites

- By Resin Type:

- Epoxy Resin

- Polyester Resin

- Vinyl Ester Resin

- Others

By Application

- Wind Turbine Blades

- Nacelle Components

- Hub and Other Structural Elements

By Installation Type

- Onshore

- Offshore

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Future Outlook

The wind turbine composites market is poised for sustained growth as governments and private sectors prioritize clean energy infrastructure. Innovations in recyclable composites, blade automation, and hybrid materials are likely to redefine manufacturing standards over the next decade. Offshore wind, in particular, is expected to be a significant growth driver due to its higher energy output and government backing. With its strategic role in enabling durable and efficient wind turbines, the composites market will remain a cornerstone of the renewable energy revolution.

Buy this Premium Research Report@https://www.visionresearchreports.com/report/checkout/41673

You can place an order or ask any questions, please feel free to contact

sales@visionresearchreports.com| +1 650-460-3308