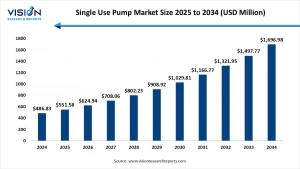

The global single-use pump market size was valued at USD 486.83 million in 2024 and it is projected to hit around USD 1,696.98 million by 2034, growing at a CAGR of 13.3% from 2025 to 2034.

Single-use Pump Market Overview

The single-use pump market is gaining traction globally as the pharmaceutical and biotechnology industries continue to shift toward disposable solutions. These pumps are designed for one-time use and offer significant advantages, including reduced risk of cross-contamination, lower operational costs, and minimized cleaning requirements. They are increasingly preferred in aseptic processes, especially in biopharmaceutical manufacturing, owing to their efficiency, safety, and adaptability.

Get a Sample@https://www.visionresearchreports.com/report/sample/40617

Single-use Pump Market Growth

With the rise in biologics and personalized medicine, pharmaceutical manufacturers are under pressure to produce smaller batches more frequently and with greater sterility assurance. Single-use pumps provide a cost-effective and scalable solution for such needs. These systems streamline processes by eliminating the need for cleaning and sterilization between production runs, saving time and resources.

Moreover, the global healthcare sector is experiencing heightened demand for flexible and mobile manufacturing capabilities. Contract manufacturing organizations (CMOs) are investing heavily in single-use systems to provide agile and compliant production environments. This trend is especially strong in emerging economies where infrastructure investments favor modular and disposable technologies.

Single-use Pump Market Trends

- Adoption in Cell & Gene Therapy: Single-use pumps are becoming essential in niche therapies that require sterile, closed-system processing ideal for cell and gene therapy manufacturing.

- Customization and Modularity: Manufacturers are designing more modular, customizable single-use pump systems to meet varying application needs across bioprocessing stages.

- Integration with Automation: Single-use systems are increasingly being integrated with sensors and automated control systems, enhancing process monitoring and data accuracy.

- Sustainability Efforts: Companies are investing in recyclable or lower-waste single-use components to address environmental concerns associated with disposables.

Revolutionizing Bioprocessing with Disposable Pumps

Single-use pumps have transformed traditional bioprocessing by offering speed, sterility, and flexibility in manufacturing operations. In contrast to conventional stainless-steel systems, which require rigorous cleaning and validation, disposable pumps enable seamless transitions between batches and product types, drastically reducing downtime. These pumps are pre-sterilized and ready for immediate use, which is critical in high-paced environments like biopharmaceutical manufacturing.

Additionally, they support modular and scalable bioprocessing architectures—key for CDMOs and biotech firms responding to rapidly changing demands in biologics, vaccines, and personalized medicine. Whether in upstream fermentation or downstream purification, these pumps simplify fluid handling and ensure contamination-free processing.

Environmental Impact and Sustainability Challenges

Despite their operational advantages, single-use systems including pumps raise valid environmental concerns. The primary challenge lies in the significant increase in plastic waste generation, which often ends up in landfills or is incinerated due to biocontamination risks. This runs counter to the growing push toward green manufacturing practices.

Moreover, recycling options for these components are limited due to the complexity of mixed materials (e.g., tubing, membranes, polymer casings). Manufacturers and industry stakeholders are now exploring innovations such as

- Use of biodegradable or recyclable materials

- Closed-loop collection programs for used disposables

- Collaborative efforts with waste management companies for sustainable disposal solutions

Sustainability will remain a key area of focus, as companies seek to balance productivity with ecological responsibility.

Cost-efficiency vs. Long-term Investment

While single-use pumps reduce upfront infrastructure costs, cleaning expenses, and downtime, organizations often question whether these savings translate into better long-term value. Here’s how the cost-efficiency plays out:

Short-term gains

- Lower capital expenditure on stainless-steel hardware.

- Elimination of cleaning validation steps.

- Reduced labor, energy, and water usage.

- Long-term considerations:

- Recurrent purchase of disposable components can accumulate costs over time.

- Environmental levies or increased waste management expenses may impact budgets.

- Single-use systems may require periodic system redesigns as processes evolve.

However, for facilities with high product turnover, small batch sizes, or multi-product pipelines (like CDMOs), the total cost of ownership still leans in favor of single-use systems due to their agility and compliance benefits.

Role in Advanced Therapies & Precision Medicine

Single-use pumps are vital enablers of next-generation therapies, such as cell and gene therapies, mRNA vaccines, and monoclonal antibodies, where sterile, small-batch production is the norm. These treatments demand high levels of contamination control, flexibility, and speed—criteria that single-use systems meet exceptionally well.

Their application in closed-system bioprocessing ensures consistent and safe handling of sensitive biological materials, reducing risks to both product integrity and patient safety. Furthermore, the modularity of single-use pumps supports fast turnaround between patients or products, aligning with the personalized nature of precision medicine.

As the healthcare industry continues to pivot toward tailor-made treatments, single-use technologies including pumps will be central to meeting these specialized production demands.

Single-use Pump Market Dynamics

Drivers

- Rising demand for biologics and biosimilars.

- Need for contamination-free and quick turnaround manufacturing processes.

- Increased outsourcing to CMOs and CROs.

Opportunities

- Growing biopharmaceutical manufacturing in Asia-Pacific and Latin America.

- Integration with digital monitoring tools for real-time analytics.

- Custom-designed single-use pump solutions for emerging therapies.

Challenges

- Environmental concerns due to increased plastic waste.

- High cost of specialized single-use components.

- Regulatory complexities in validating single-use systems.

Applications in the Market

Single-use pumps have become essential tools across various segments of the life sciences and healthcare industries due to their sterility, flexibility, and ease of use. In biopharmaceutical manufacturing, these pumps are widely utilized for sterile liquid transfer in both upstream (fermentation, cell culture) and downstream (filtration, purification) processing. They eliminate the need for cleaning validation between batches, streamlining production and ensuring contamination-free operations.

In the field of cell therapy, single-use pumps play a critical role in maintaining the accuracy and sterility of sensitive cell-culture workflows. These therapies often involve patient-specific treatments that require closed-system processing, making disposable pumps a reliable solution for ensuring both safety and consistency.

Case Study Adoption of Single-use Pumps in mRNA Vaccine Production

A leading global pharmaceutical company integrated single-use peristaltic pumps in their mRNA vaccine production facility during the COVID-19 pandemic. The implementation reduced setup time by 60% and eliminated cross-contamination risks. The disposable design allowed the company to scale production efficiently, meeting the sudden surge in global demand while maintaining strict sterility and quality control standards.

Read More:https://www.heathcareinsights.com/u-s-attention-deficit-hyperactivity-disorder-market/

Top Companies in Single-use Pump Market

- PSG Dover

- Watson-Marlow Fluid Technology Group

- Levitronix GmbH

- Cole-Parmer Instrument Company, LLC

- Masterflex (An Antylia Scientific Company)

- Verder Group

- Almatec (A Brand of PSG Dover)

- Biopure (A Brand of Watson-Marlow)

- PreFluid Technology Co., Ltd.

- KNF Neuberger GmbH

Want custom data? Click here: https://www.visionresearchreports.com/report/customization/40617

Market Segmentation

By Product

- Equipment

- Peristaltic pumps

- Quaternary diaphragm pump

- Centrifugal pumps

- Others

- Accessories

By Material

- Polypropylene (PP) Pumps

- Polyethylene (PE) Pumps

- Others

By End-use

- Biopharmaceutical & Pharmaceutical Companies

- CROs & CMOs

- Academic & Research Institutes

- Others

Future Outlook

The single-use pump market is expected to continue its upward trajectory, driven by continuous innovation in bioprocessing and the growing need for agile manufacturing. Future developments may include eco-friendly disposables, AI-driven process optimization, and next-gen modular single-use systems. The industry’s focus will likely shift toward balancing sustainability with efficiency, driving R&D in recyclable materials and circular design principles.

Buy this Premium Research Report@https://www.visionresearchreports.com/report/checkout/40617

You can place an order or ask any questions, please feel free to contact

sales@visionresearchreports.com| +1 650-460-3308