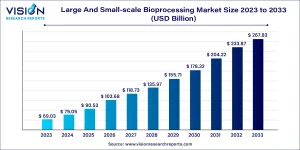

The large and small-scale bioprocessing market size is anticipated to grow significantly, reaching over USD 267.83 billion by 2033 from an estimated USD 69.03 billion in 2023, representing a CAGR of 14.52%.

Understanding Bioprocessing: Big and Small

Bioprocessing refers to the use of living cells or their components like enzymes or microorganisms to manufacture useful products. It’s the backbone of biotechnology, helping create medicines, vaccines, enzymes, and other biologically derived products.

Small-scale bioprocessing is typically used in research labs, pilot studies, and early-stage drug development. These systems allow scientists to experiment with new processes, test formulations, and optimize production before moving to larger quantities. They are flexible, cost-effective, and easy to handle, making them ideal for innovation and experimentation.

Access Your Sample Report Today: https://www.visionresearchreports.com/report/sample/40864

Large and Small-Scale Bioprocessing Market Overview

The large and small-scale bioprocessing market plays a crucial role in the biotechnology and pharmaceutical sectors, supporting the development, production, and purification of biological products such as vaccines, monoclonal antibodies, enzymes, and other therapeutic proteins. Bioprocessing integrates biological, chemical, and engineering principles to optimize processes for producing high-quality bioproducts. The market includes both small-scale bioprocessing platforms used for research and pilot studies, as well as large-scale systems designed for commercial production.

Large and Small-Scale Bioprocessing Market Growth

The bioprocessing industry has witnessed significant growth due to the rising demand for biologics and biopharmaceuticals, coupled with increasing investments in research and development. Advancements in bioreactor technologies, automation, and single-use systems have accelerated process efficiency, enabling faster production cycles and higher product yields.

Additionally, the growing prevalence of chronic diseases, infectious diseases, and personalized medicine has fueled the need for efficient and scalable bioprocessing solutions. Pharmaceutical companies and contract manufacturing organizations (CMOs) are increasingly adopting both small- and large-scale bioprocessing platforms to meet regulatory standards while reducing production costs.

How Bioprocessing is Changing Healthcare

Bioprocessing has revolutionized modern medicine by enabling the production of advanced therapies that were previously impossible to manufacture. Vaccines, monoclonal antibodies, and gene therapies all rely on precise bioprocessing methods to ensure safety, effectiveness, and scalability.

By integrating automation, digital monitoring, and high-throughput technologies, bioprocessing helps pharmaceutical companies produce therapies faster and more efficiently. Personalized medicine, which tailors treatments to individual patients, is heavily dependent on small- and large-scale bioprocessing platforms. This allows for rapid production of custom biologics and reduces the time from lab discovery to patient treatment.

Types of Bioprocessing Systems

Bioprocessing systems can be broadly classified based on scale and technology:

Large-scale systems:

- Used for commercial production.

- Involve stainless steel bioreactors or hybrid systems.

- Offer high consistency, scalability, and regulatory compliance.

Small-scale systems:

- Ideal for research, pilot studies, and process optimization.

- Flexible, cost-effective, and easier to operate.

- Used in early-stage drug development or experimental therapies.

Single-use systems:

- Disposable bioreactors and components reduce contamination risk.

- Lower cleaning and maintenance costs.

- Widely adopted in both small- and large-scale applications for flexibility.

Traditional systems:

- Stainless steel bioreactors and equipment used for large-scale, long-term production.

- Require higher maintenance but offer proven reliability for established processes.

Large and Small-Scale Bioprocessing Market Trends

- Single-Use Bioreactors: Adoption of single-use systems has increased due to their flexibility, reduced contamination risk, and lower operational costs, especially in small-scale and pilot-scale processes.

- Automation and Digitalization: Advanced automation tools, sensors, and process analytical technologies (PAT) are enhancing process control, reproducibility, and data analytics in bioprocessing.

- Sustainable Bioprocessing: Companies are focusing on eco-friendly production methods, including energy-efficient systems, waste reduction, and recycling of bioprocessing materials.

- Hybrid Manufacturing Approaches: The combination of traditional large-scale stainless steel systems with modern single-use technologies is gaining traction to optimize scalability and cost-efficiency.

Large and Small-Scale Bioprocessing Market Dynamics

Drivers

The market is driven by the rising adoption of biologics and biosimilars, increasing demand for personalized medicine, and technological advancements in bioprocessing platforms. Additionally, regulatory support for innovative therapies and the expansion of contract manufacturing services are propelling market growth.

Opportunities

There is substantial growth potential in emerging economies due to expanding biotechnology sectors and rising healthcare expenditures. Innovations in continuous processing, cell-free production systems, and artificial intelligence-driven process optimization present new avenues for market expansion.

Challenges

High initial investment costs for advanced bioprocessing equipment, complex regulatory requirements, and technical challenges related to scale-up and reproducibility remain significant hurdles for market players.

Want custom data? Click here: https://www.visionresearchreports.com/report/customization/40864

This strategic integration offered several benefits:

- Reduced Production Time: Streamlined workflows and faster batch cycles accelerated the manufacturing process.

- Lower Operational Costs: Single-use systems minimized cleaning and maintenance requirements, reducing labor and downtime.

- Improved Consistency: Combining advanced monitoring with standardized processes ensured batch-to-batch uniformity, critical for therapeutic effectiveness.

As a result, the company was able to increase production capacity, meet global demand more efficiently, and maintain strict regulatory compliance.

Case Study: Optimizing Monoclonal Antibody Production

A leading global biopharmaceutical company faced challenges in meeting the rising demand for a monoclonal antibody used in cancer therapy.

To address production inefficiencies and reduce costs, the company implemented a hybrid bioprocessing platform that combined single-use bioreactors with traditional stainless-steel systems.

This strategic integration offered several benefits:

- Reduced Production Time: Streamlined workflows and faster batch cycles accelerated the manufacturing process.

- Lower Operational Costs: Single-use systems minimized cleaning and maintenance requirements, reducing labor and downtime.

- Improved Consistency: Combining advanced monitoring with standardized processes ensured batch-to-batch uniformity, critical for therapeutic effectiveness.

Read More: https://www.heathcareinsights.com/disposable-bronchoscope-market/

Large And Small-scale Bioprocessing Market Key Players

- Merck KGaA

- Thermo Fisher Scientific, Inc.

- GE healthcare

- Corning, Inc.

- Sartorius AG

- CESCO BIOENGINEERING CO., LTD

- Bio-Process Group

- Bioprocess Control AB

- Eppendorf AG

Market Report Segmentations:

By Scale

- Industrial Scale (Over 50,000 Litre)

- Small Scale (Less Than 50,000 Litre)

By Workflow

- Downstream Processing

- Fermentation

- Upstream Processing

By Product

- Bioreactors/Fermenters

- Cell Culture Products

- Filtration Assemblies

- Bioreactors Accessories

- Bags & Containers

- Others

By Application

- Biopharmaceuticals

- Speciality Industrial Chemicals

- Environmental Aids

By Use Type

- Multi Use

- Single Use

By Mode

- In-house

- Outsourced

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Looking Ahead: The Future of Bioprocessing

The future of bioprocessing is poised for rapid innovation. Emerging technologies like continuous manufacturing, AI-driven process optimization, and advanced single-use bioreactors are reshaping how biologics are developed and produced.

Personalized medicine will increasingly rely on flexible small-scale platforms for custom therapies, while large-scale systems will continue to ensure global supply of essential biologics. Sustainability is also becoming a key focus, with companies adopting energy-efficient systems, waste reduction techniques, and eco-friendly materials in bioprocessing.

Buy this Premium Research Report@ https://www.visionresearchreports.com/report/checkout/40864

You can place an order or ask any questions, please feel free to contact

sales@visionresearchreports.com| +1 650-460-3308