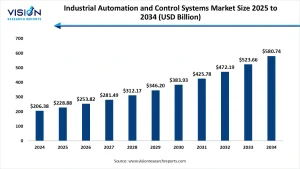

The global industrial automation and control market size was estimated at USD 206.38 billion in 2024 and it is projected to hit around USD 580.74 billion by 2034, growing at a CAGR of 10.9% from 2025 to 2034.

Industrial Automation and Control Market Overview

The industrial automation and control market is undergoing a significant transformation, playing a central role in modernizing manufacturing operations across the globe. With rapid advancements in technologies such as IoT, AI, robotics, and machine learning, automation systems are being widely adopted to streamline production, reduce human error, and improve operational efficiency.

As industries aim for smarter, safer, and more connected operations, the demand for advanced control systems and automation solutions is accelerating. From automotive to pharmaceuticals, nearly every sector is embracing automation to remain competitive in an increasingly digital economy.

Get a Sample@ https://www.visionresearchreports.com/report/sample/41769

Industrial Automation and Control Market Growth

The global industrial automation and control market size was estimated at USD 206.38 billion in 2024, and it is projected to reach USD 580.74 billion by 2034, growing at a robust CAGR of 10.9% from 2025 to 2034. This growth is driven by the increasing need for efficiency, reduced operational costs, and enhanced product quality across industries.

The rapid shift towards Industry 4.0, which emphasizes smart manufacturing and data exchange, is further fueling the adoption of automation technologies. As businesses seek to mitigate risks, reduce downtime, and optimize resources, the deployment of integrated control systems is becoming a strategic imperative.

What Is Industrial Automation?

Industrial automation refers to the use of machines, control systems, and technology to handle different tasks in factories and industrial settings with minimal human help. These systems can perform repetitive jobs, monitor processes, and make adjustments in real-time to improve production. Automation includes hardware like sensors and robots, as well as software that manages operations smoothly and efficiently.

Industrial Automation and Control Market Trends

- Rise of Smart Factories: Industry 4.0 is propelling the development of intelligent manufacturing units with real-time monitoring, predictive maintenance, and AI-driven process optimization.

- Integration of AI and Machine Learning: AI-enabled automation is improving decision-making processes, enabling predictive analytics, and driving operational excellence across sectors.

- Growing Use of Industrial IoT (IIoT): IoT allows machines, sensors, and systems to communicate, collect, and analyze data, providing actionable insights and improving efficiency.

- Adoption of Cloud-Based Automation Platforms: Companies are shifting to cloud and edge computing to support remote operations, real-time control, and scalable automation deployments.

Industrial Automation and Control Market Dynamics

Drivers

- Rising demand for productivity and efficiency in manufacturing

- Need for real-time data analytics and predictive maintenance

- Expansion of industrial robotics and smart sensors

Opportunities

- Increasing investment in Industry 4.0 and smart infrastructure

- Untapped potential in emerging economies for automation adoption

- Surge in demand for customized and flexible automation solutions

Challenges

- High initial investment and integration costs

- Cybersecurity threats associated with connected systems

- Lack of skilled workforce for managing advanced automation

Why Automation Matters Today?

Automation is important because it helps industries produce more in less time, with fewer errors. It lowers the cost of labor and energy, improves product quality, and ensures worker safety by handling dangerous or heavy tasks. In today’s competitive market, companies need to be fast and flexible. Automation provides the tools to keep up with demand, adapt to changes, and reduce waste. It also supports 24/7 operations, which boosts overall productivity.

Big Opportunities in the Market

- Growing Use in Small and Mid-Sized Companies: As technology becomes more affordable, smaller factories are starting to adopt automation to stay competitive.

- Expansion in Emerging Economies: Countries in Asia, Africa, and Latin America are investing in manufacturing, creating a big need for automation tools and systems.

- Smart Manufacturing and Industry 4.0: The shift to digital and connected factories is opening up new business models, including remote monitoring and predictive maintenance.

- Green and Energy-Efficient Solutions: Companies are looking for ways to cut energy use and emissions automation helps by optimizing every step of the production process.

Where Automation Is Used the Most

Automation is widely used in industries that need high-speed, high-precision operations. Some of the key areas include:

- Automotive Manufacturing: Robots and machines are used for welding, painting, assembly, and inspection to ensure consistency and safety.

- Electronics Industry: Automation helps build tiny components with extreme accuracy, improving efficiency and reducing human error.

- Food and Beverage: Machines handle sorting, packing, and quality checks to maintain hygiene and speed up delivery.

- Pharmaceuticals: Automation is used in drug production and packaging, ensuring precise dosage and compliance with safety rules.

Applications in the Market

Industrial automation and control systems are widely used across a range of industries to enhance productivity, accuracy, and safety. In the automotive sector, automation plays a crucial role in assembly line operations, robotic welding, and quality control, enabling faster and more consistent vehicle production. In the oil and gas industry, these systems are used for real-time monitoring of pipelines, drilling sites, and refining processes, helping to maintain safety and operational efficiency. The pharmaceutical industry relies on automation for precise batch control, sterile packaging, and compliance with regulatory standards. In food and beverage manufacturing, automated systems handle sorting, packaging, and quality checks to ensure hygiene and reduce waste. The electronics industry uses automation for high-speed assembly, testing, and defect detection, which is essential in producing small and complex components with high precision.

Case Study Siemens and the Smart Factory Transformation

Siemens partnered with a leading automotive manufacturer to implement a fully automated production line using its SIMATIC automation systems. By integrating PLCs, HMIs, and SCADA into a unified network, the client reduced downtime by 30% and increased throughput by 20% within one year. Predictive analytics also enabled the detection of component failures before they occurred, saving significant maintenance costs.

Read More:https://www.heathcareinsights.com/u-s-anatomic-pathology-market/

Top Companies in Industrial Automation and Control Market

- ABB Ltd.

- Emerson Electric Co.

- Honeywell International, Inc.

- Kawasaki Heavy Industries, Ltd.

- Mitsubishi Electric Corporation

- OMRON Corporation

- Rockwell Automation, Inc.

- Schneider Electric

- Siemens AG

- Yokogawa Electric Corporation

Want custom data? Click here: https://www.visionresearchreports.com/report/customization/41769

Market Segmentation

By Control System

- DCS

- PLC

- SCADA

- Others

By Component

- HMI

- Industrial Robots

- Control Valves

- Sensors

- Others

By End Use

- Aerospace & Defense

- Automotive

- Chemical

- Energy & Utilities

- Food & Beverage

- Healthcare

- Manufacturing

- Mining & Metal

- Oil & Gas

- Transportation

- Others

By Regional

- North America

- U.S.

- Canada

- Mexico

- Europe

- UK

- Germany

- France

- Asia Pacific

- China

- India

- Japan

- South Korea

- Australia

- Latin America

- Brazil

- Middle East & Africa

- UAE

- South Africa

- Saudi Arabia

Future Outlook

The future of the industrial automation and control market is deeply tied to innovation. Emerging technologies such as 5G, augmented reality, digital twins, and blockchain will further enhance connectivity, transparency, and resilience in industrial operations. The focus will be on building autonomous factories capable of learning, adapting, and self-optimizing in real time. Sustainability becomes a business priority, automation will help companies monitor energy use, reduce emissions, and ensure regulatory compliance making green manufacturing a tangible reality.

Buy this Premium Research Report@https://www.visionresearchreports.com/report/checkout/41769

You can place an order or ask any questions, please feel free to contact

sales@visionresearchreports.com| +1 650-460-3308